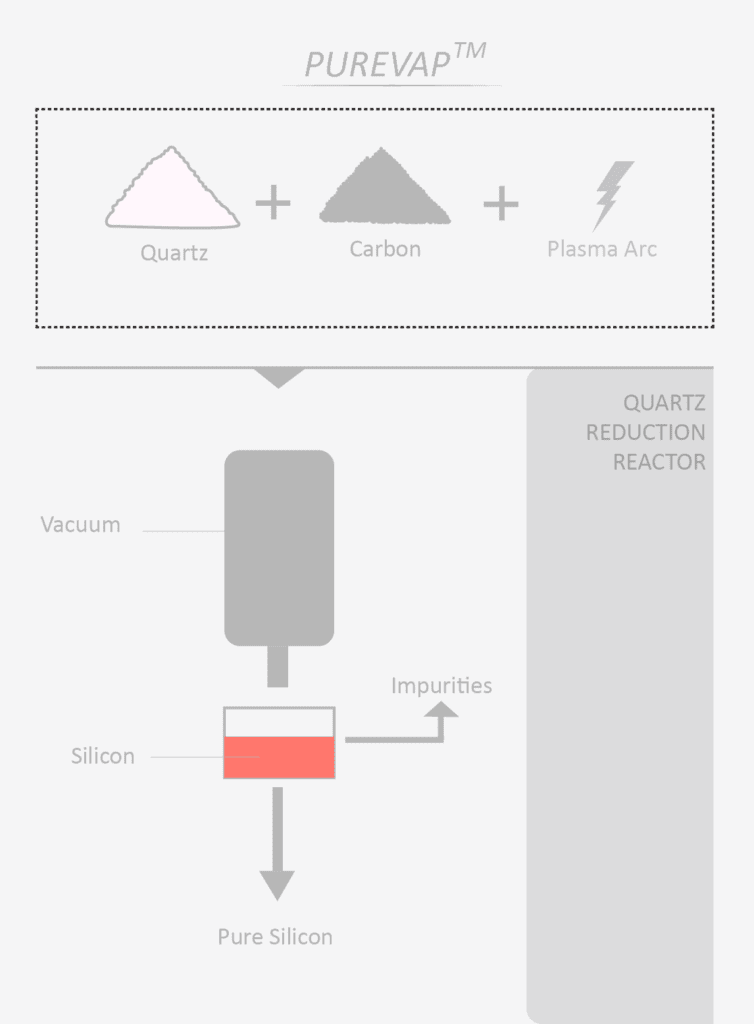

PUREVAP™

High Purity Silicon

PUREVAP™ is a patented one-step process that uses a plasma arc within a vacuum furnace to produce high purity metallurgical grade silicon and solar grade silicon from quartz. Developed by PyroGenesis and then sold to HPQ Silicon, the two companies continue to work collaboratively on PUREVAP™ projects and its expected that the silicon grades produced by PUREVAP™ could be used for different applications, including solar energy.

BENEFITS:

- One-step direct transformation process;

- Lower cost for producing silicon compared to current practices;

- Lower CO2 than current processes;

- Remove impurities: Phosphate, Potassium, Magnesium, Zinc, Calcium, and other elements.

HOW IT WORKS:

PUREVAPTM reduces the quartz with carbon using a plasma submerged arc. Under vacuum, and at very low operating pressure, the silicon is refined in a one-step process removing all impurities and transforming it to its purest form, resulting in a high purity silicon.